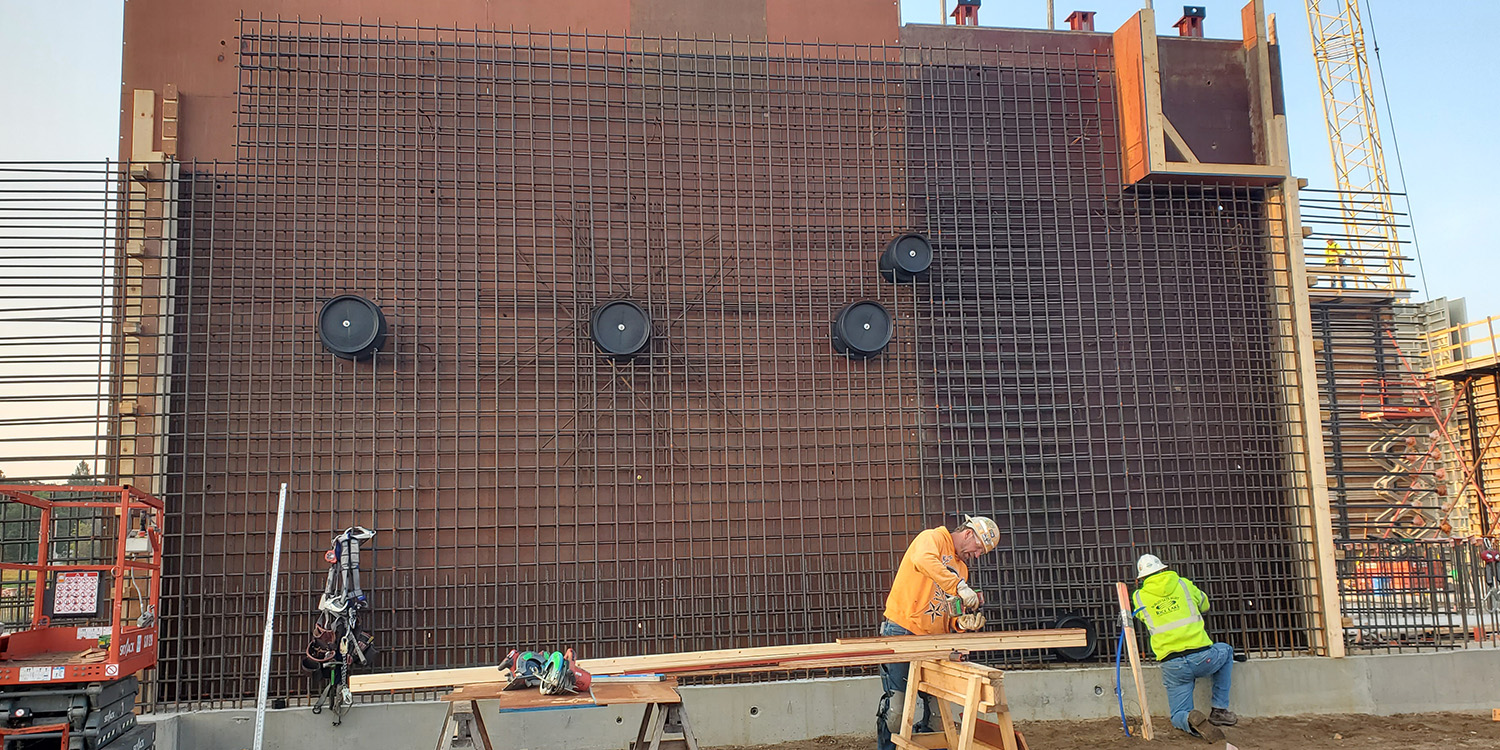

CASE STUDIES

Cold Spring Industrial Pretreatment Facility

Cold Spring, MN

Project Overview

To normalize the industrial flows to municipal quality, this pretreatment facility included tanks, odor control, flare, pumping, piping, mechanical, electrical, and chemical feed systems, site construction, and other related items, including installing a proprietary low rate anaerobic process followed by an aerobic/SBR reactor. All influent industrial flow is diverted through this new facility to reduce pH, sugars, and alkalinity. Once through the pretreatment facility, the industrial effluent continues through the existing plant for treatment. This project helps stabilize the plant chemistry.

This construction involved extensive coordination with the two programs and equipment designers to validate control logic. During start-up, plant effluent circulated to check the programming and debug the controls.

Location

Cold Spring, MN

Project Delivery

Design-Bid-Build

Role

General Contractor

Value:

$18,674,742

By the Numbers

0.4

MGD Industrial Flow

2

Distinct I&C Systems

3.2

Million Gallon Bulk Volume Fermenter

90

Degrees Temperature for Sludge

74.2%

Self-Performance

403

IO points